- Whilst Tesla now exists as a global EV brand with large production facilities located across the world, it wasn’t always this way, with the whole journey being over 20 years in the making.

- Yet, much of the physical foundations of its first production car, the Tesla Roadster, was laid not in California, but in a factory near a small English village.

- This is the story of how then-British-owned Lotus played a key role in helping Tesla bring the original Roadster to market.

The first Tesla Roadster: Built in the UK, refined in California

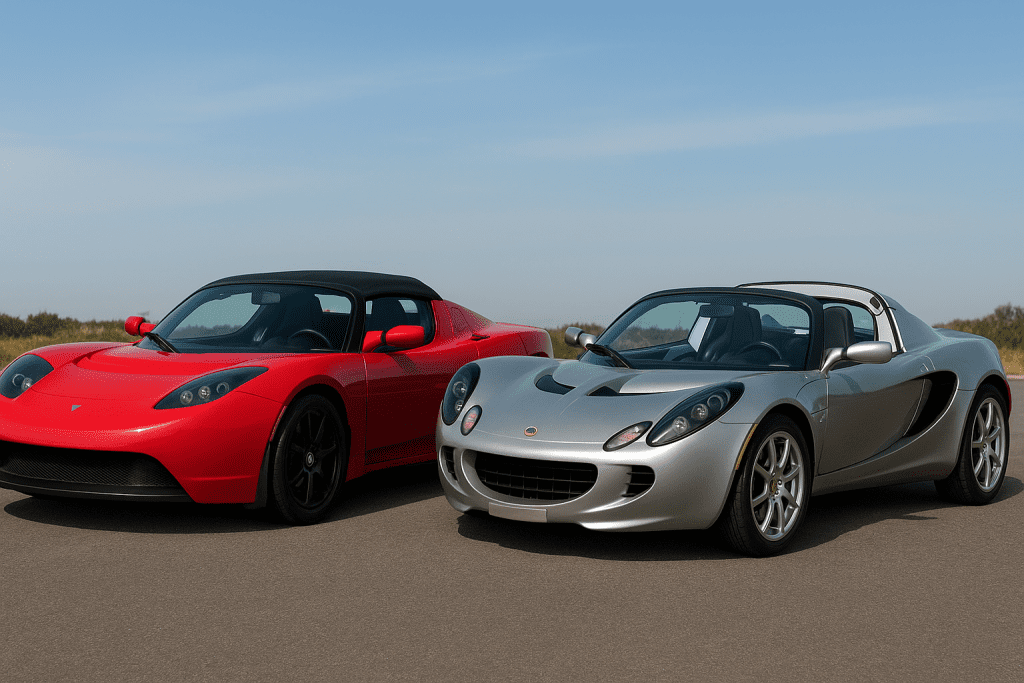

The proportional similarities between the original Tesla Roadster and the now-discontinued Lotus Elise are no coincidence. Tesla’s origins begin in the early 2000s, with the original co-founders wanting to produce a lightweight, fully-electric sports car. It became clear that building their own sports car platform from scratch would be prohibitive and expensive, and after seeing the Lotus Elise be officially released for the US market at the 2004 LA Auto Show, the group had a brainwave. By summer of 2005, Lotus and Tesla had signed an agreement in which Lotus would assist with research and development, and produce a ‘glider’ sports car chassis – essentially a complete car and chassis, without any engine or drivetrain, ready for Tesla to implement its own propulsion system into.

This ‘glider’ chassis was produced at Lotus’ factory in Hethel, on the same production line as Lotus models then being produced such as the Elise and Exige. Despite being produced on the same production line, the Roadster was far from simply being a Lotus Elise with an electric motor crudely dropped in. This included extensive modifications to the aluminium frame to support the weight of over 400 kilograms of lithium-ion batteries, and changes to ensure the suspension could cope with this extra weight whilst still maintaining the strong driving dynamics that Lotus’ own models were renowned for.

Finished glider models produced by Lotus were then transported to Tesla’s now-closed Menlo Park facility, in California, where final production including the addition of electric motors, computers, and batteries, took place. This small factory is a far cry from the millions of square foot gigafactories that current Tesla models are produced in.

It’s estimated that the final production Tesla Roadster shared just 7% of its overall parts with the Lotus Elise, such as the windscreen and many interior fittings. Even so, the partnership was a brilliant shortcut, helping Tesla to speed up production and type approval of its Roadster, which saw official production start in early 2008, less than three years since Lotus and Tesla originally signed their glider agreement – almost an early example of the so-called ‘China speed’ which all manufacturers are hoping to achieve.

The original Tesla Roadster only sold in small numbers, with approximately 2,450 examples produced before model production came to a close around 2012. Still, it laid the groundworks for the mass-produced 2012 Tesla Model S, and has eventually lead to a global best-seller, the Tesla Model Y, with the original journey starting partly with the help of a small British automaker.

When it comes to Lotus in the present day, the firm is now majority-owned by China’s Geely. It currently offers two fully-electric models, the Emeya saloon and the Eletre SUV. We’re yet to see a lightweight electric sports car come from the Lotus brand – but newcomer British brand Longbow, founded by ex-Tesla and Lucid executives, has quickly filled that niche, with its new sub-900kg Longbow Speedster EV.

The following video from Doug DeMuro goes to show just how far Tesla has come from its first production car, the Roadster.